Hauni filter system improves efficiency

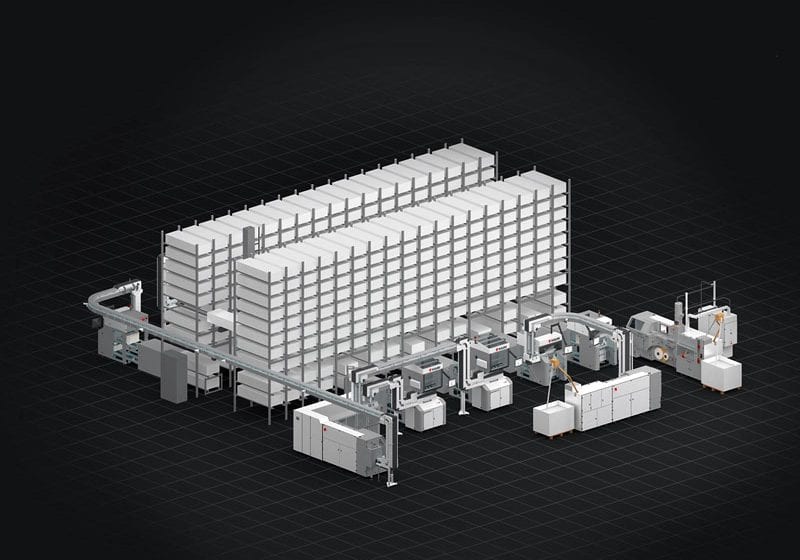

Hauni’s new high-bay storage system allows cigarette manufacturers to separate filter making from the cigarette production process.

Hauni Maschinenbau is introducing a new all-automatic high-bay storage system that allows cigarette makers to separate filter making from the cigarette production process.

Apart from maximizing machine utilization, the system’s space-saving storage unit keeps filters ready for use wherever and whenever required.

“This storage system keeps the filter and cigarette manufacturing processes separate, allowing filter and cigarette makers to achieve optimum utilization figures,” says Patrick Fricke, head of customer project management engineering at Hauni. “A hitch on one machine won’t automatically bring the entire production process to a halt as it soon would with makers in a fixed link-up.”

When connected to a high-bay storage system, filter makers can be kept running for as long as required. They can even manufacture filters for several shifts in advance, thereby omitting the need for night shifts. This not only improves machine utilization but also dispenses with the need to keep switching from one filter specification to another.

Having a variety of rod types on hand gives manufacturers the flexibility to make smaller batch sizes. The variety in brands and cigarette formats has risen sharply in recent years, and this trend is likely to continue.

Another benefit is that the filters stored in this system have time to cure adequately, ensuring smooth processing during cigarette making.

Storage systems of this type can also help minimize errors in the manufacturing process, particularly when producing multifilters.

Part of Hauni’s system-integration concept, the storage system is supplied by Dematic of Germany.

The system is designed to work smoothly with Hauni’s tray fillers and dischargers. “Manufacturing companies can continue using their existing equipment without needing to buy extra machines,” says Fricke. “Also, existing trays can continue to be used.”

According to Hauni, storage systems installed at two Chinese production facilities operate in perfect harmony with the machines linked to them. Another system is currently being set up in America.