U.S. Market Poised for Disruption

Starting next month, PMI will be free to compete with its bestselling noncigarette brand.

Starting next month, PMI will be free to compete with its bestselling noncigarette brand.

Doctors should talk with patients about the relative risks of products, say researchers.

The suit challenges the legislation on constitutional grounds.

Turin has banned outdoor smoking unless others are a least five meters away.

Income from the purchase and sale of currency reached RUB2.56 billion last year.

Geographical references may not be used for non-Cuban cigar products.

Mustafa is the SVP of business communications and sustainability for Reynolds.

While reduced-risk products have a role, abstinence should be the goal, says Director King.

The group reports “unprecedented interest” with an increase in retail accounts.

The bill will now progress to the next stage in parliament, where it can be subject to amendment.

Olczak expresses confidence in local farmers’ ability to deliver the required quality.

The South Korean cigarette firm assists growers struggling with labor shortages.

Several of the products were inaccurately described as flavorless, according to FDA.

The company says it wants to correct misinformation abouts its nicotine pouch.

Former British Prime Minister Boris Johnson describes the plans as ‘nuts.’

The proposed law would prohibit the circulation of ENDS products within the country.

Click on a country to view its latest news from the tobacco and vapor industries.

Heated-tobacco products continue to gain momentum, although consumption patterns are shifting.

COP10 is unlikely to significantly accelerate progress toward the FCTC objectives.

Vice Ventures has carved out a niche investing in good companies in “bad” industries.

A supplier of product labeling solutions claims its technology had helped shrink the Russian illicit cigarette market by a quarter.

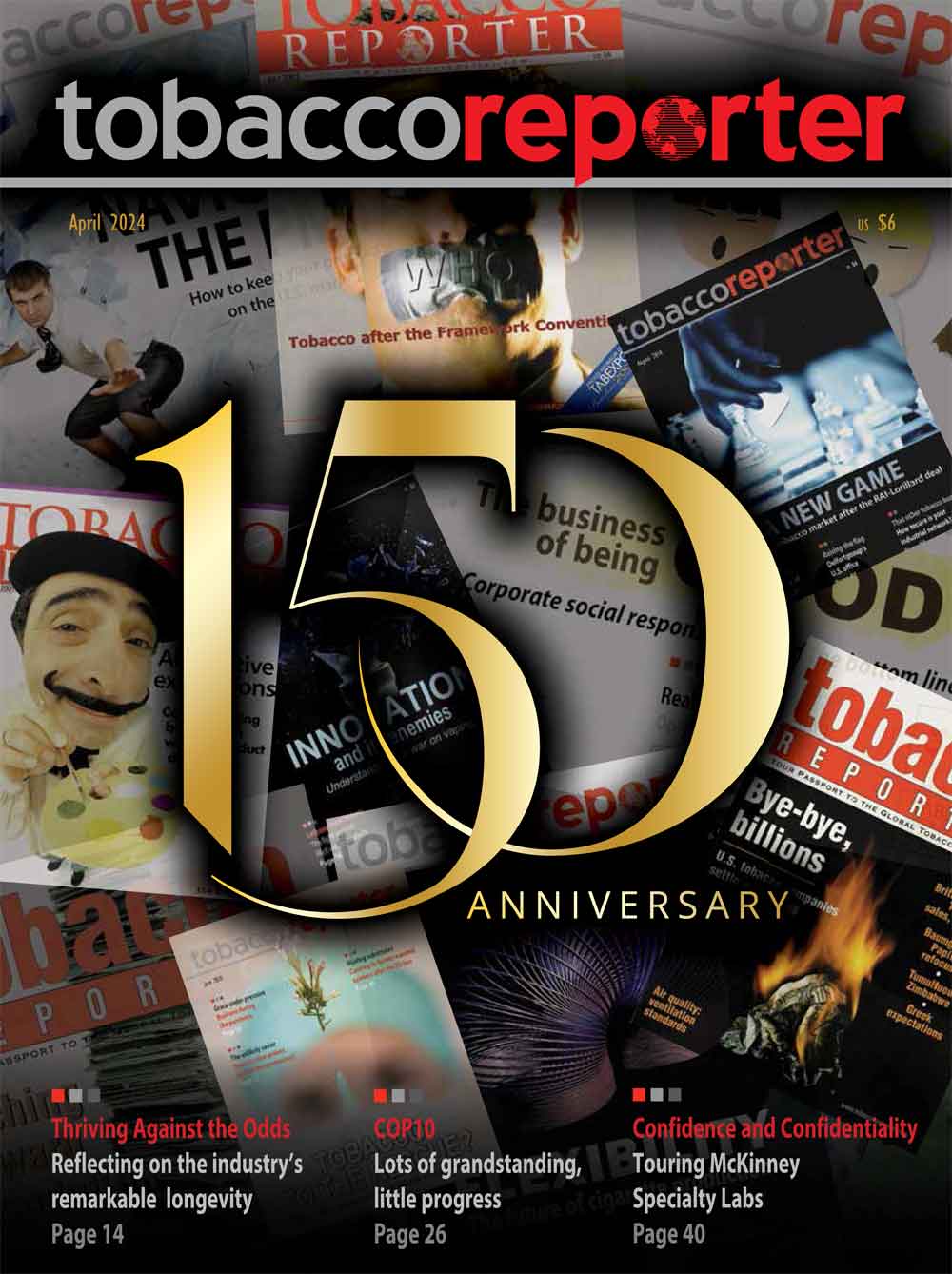

Pondering the industry’s remarkable longevity as Tobacco Reporter celebrates its 150th anniversary.

Three years into its five-year strategy, Imperial Brands reports progress on multiple fronts.

McKinney Specialty Labs has the expertise to generate trustworthy data and the discretion to share it only with authorized users.

Cuba’s cigar industry is on the road to recovery after several challenging years.

This year marks our publication’s 150th anniversary. To celebrate, our April 2024 issue reflects not only on a century and a half of editorial excellence, but also on the remarkable endurance of the nicotine business in an increasingly challenging operating environment. What is the secret of its success?

Unfortunately, there was less to brag about by the parties to the Framework Convention on Tobacco Control, which held their 10th meeting recently. As Stefanie Rossel reports in this issue, the Panama gathering featured lots of grandstanding but marked little progress toward the treaty’s goal of reducing the health impact of smoking.

Cheryl Olson investigated where the industry stands with ESG. Even as the term is falling out of fashion in some quarters, she found that the nicotine business remains firmly committed to the concept.

Timothy Donahue reports from the Habanos cigar festival in Cuba and Catharine Dockery shared with us the business strategy of her Vice Ventures fund, which specializes in good companies in supposedly bad industries.

Also in this issue: A profile of McKinney Specialty Labs in Richmond.

Brazilian lawmakers mull regulation of e-cigarettes, which despite being illegal remain widely available in the country.

Boosting efficiencies may help tobacco companies cope with tough times, according to CME Automation.

Banning e-liquid flavors may not achieve the outcomes that proponents of that measure have in mind.

Odiri Erewa-Meggison reflects on the significance of BAT’s Ibadan factory in Nigeria.

Though a generational tobacco ban is not without merit, the U.K. will not allow it to work in the way that it could—and thus the measure should be shelved, writes George Gay.

The company partners with 12 of the world’s leading vaping companies.

Filtrona partners with Greenbutts to expand its range of sustainable filter offerings.

The broken U.S. new tobacco product application process revealed by the numbers

Intangible assets remain a major contributor to the real value generated by the tobacco industry.

Two years into the Ukrainian conflict, businesses in the tobacco industry still scramble to adapt.

Having weathered the supply disruptions of Covid-19, tobacco freight forwarders must now dodge missiles in one of the world’s busiest waterways.

German software supplier Fluxcode has developed a track-and-trace solution for all needs.