Suppliers of adhesives and glue application systems prepare to accommodate new product requirements.Read More

Tags :H.B. fuller

She brings more than 30 years of relevant experience. Read More

Mastin has more than more than 30 years’ experience in manufacturing.Read More

H.B. Fuller—a leading global adhesives provider focusing on perfecting adhesives, sealants and other specialty chemical products—has opened its Luneburg Adhesive Academy. Located in Germany, the Luneburg Adhesive Academy is the company’s Read More

Adhesives provider H.B. Fuller has broken ground for a new technical center at its existing site in Lüneburg, Germany. The ceremony, on Aug. 12, was attended by Mayor Ulrich Mädge, along with representatives Read More

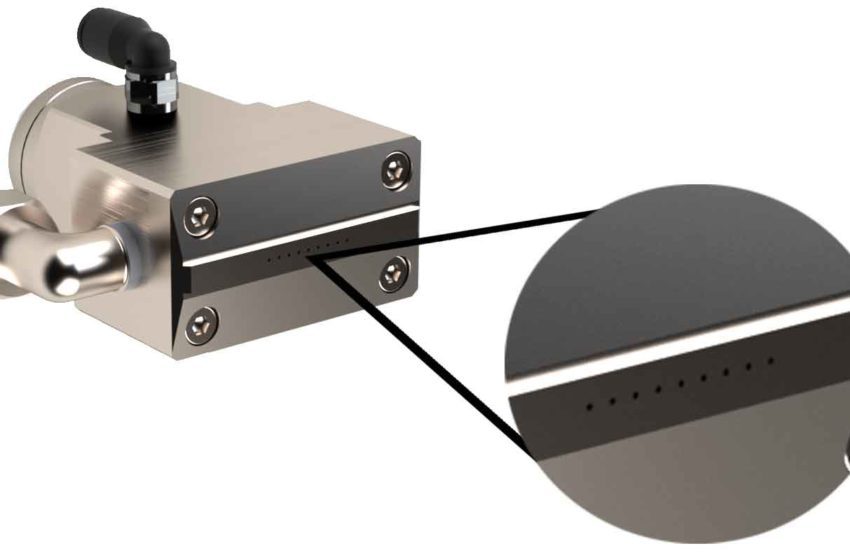

H.B. Fuller has introduced Ipacoll 2603, a high-performance tipping adhesive for both skip-tip and full-coat slot nozzle applicators. Tailor-made to fulfill the requirements of Hauni Maschinenbau’s high-speed Protos M5 and M8 machines, it supports Read More